Collaborators

(Internal): Seyed Mohammad Reza Taheri

(External): Ali Sanjari (Jetco Co.)

(International):

Mohsen Moazzami Gudarzi (University of Manchester), Alexandara Satalov (Leibniz University)

(Internal): Seyed Mohammad Reza Taheri

(External): Ali Sanjari (Jetco Co.)

(International):

Mohsen Moazzami Gudarzi (University of Manchester), Alexandara Satalov (Leibniz University)

Funded by

IPM

IPM

Published Papers

1- Anomalously low electrostatic bending stiffness of graphene oxide 2D membranes regulates their environmental fate in aquatic ecosystems, Journal of Materials Chemistry A, 2022

2- Correlation of interfacial dilational rheology and processing of 2D Materials liquid crystals: A case-study of graphene oxide liquid crystal phases, Iranian Journal of Physics Research 20 (3), 515-524, 2020

3- Laser-assisted tunable optical nonlinearity in liquid-phase exfoliated MoS2 dispersion, Applied Physics A 124 (10), 692, 2018

4- Superflexibility of Graphene Oxide, PNAS, 2016, 113 (40), 11088-11093

5- Processable 2D materials beyond graphene: MoS2 liquid crystals and fibers, Nanoscale 2016, 8 (38), 16862-16867

6- Liquid crystal mediated self-assembly of porous α-Fe2O3 nanorods on PEDOT:PSS functionalized graphene as a flexible ternary architecture for capacitive energy storage, Particle and Particle Systems Characterization, 2016. 33 (1) : p.27-37

7- Self-assembled multifunctional hybrids: Towards architecting high-performance graphene-based energy storage devices, ACS Central Science, 2015. 1(4): p.206-216

8- Graphene oxide dispersions: tuning rheology to enable fabrication, Materials Horizons, 2014. 1 (3): p.326-331

9- Formation and processability of liquid crystalline dispersions of graphene oxide. Materials Horizons, 2014. 1(1): p. 87-91

10- Spray Pyrolysis of liquid crystalline dispersions of graphene oxide based hybrids: a practical approach towards next generation of 3D isotropic architectures for energy storage applications, Particle and Particle Systems Characterization, 2014

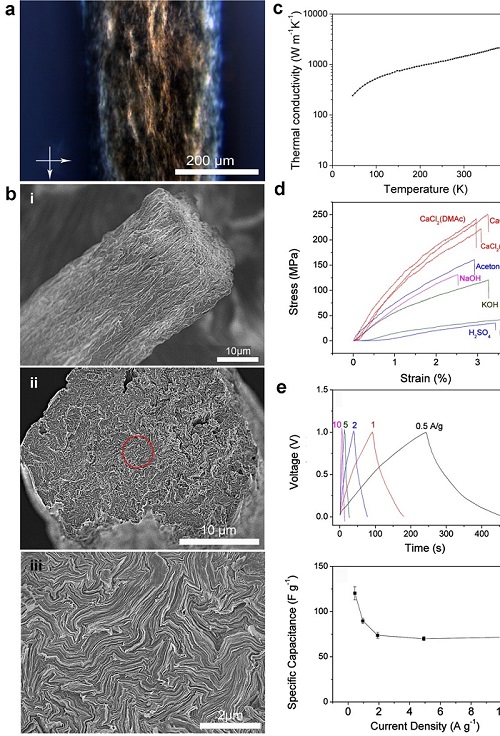

11- Scalable One‐Step Wet‐Spinning of Graphene Fibers and Yarns from Liquid Crystalline Dispersions of Graphene Oxide: Towards Multifunctional Textiles. Advanced Functional Materials, 2013. 23(43): p. 5345-5354

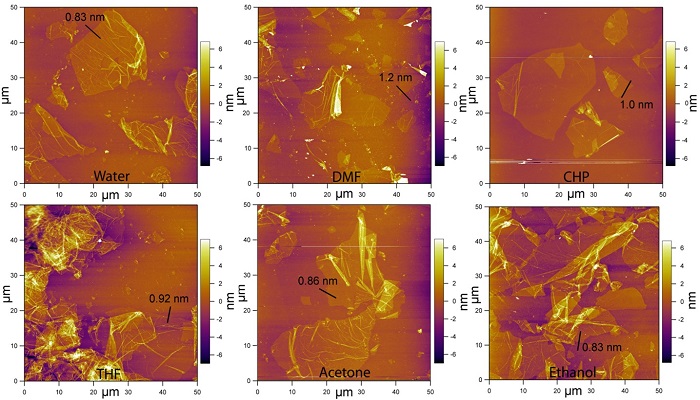

12- Organic Solvent-Based Graphene Oxide Liquid Crystals: A Facile Route toward the Next Generation of Self-Assembled Layer-by-Layer Multifunctional 3D Architectures. ACS nano, 2013. 7(5): p. 3981-3990

13- Self-alignment and high electrical conductivity of ultralarge graphene oxide–polyurethane nanocomposites. Journal of Materials Chemistry, 2012. 22(25): p. 12709-12717

14- Spontaneous formation of liquid crystals in ultralarge graphene oxide dispersions. Advanced Functional Materials, 2011. 21(15): p. 2978-2988

1- Anomalously low electrostatic bending stiffness of graphene oxide 2D membranes regulates their environmental fate in aquatic ecosystems, Journal of Materials Chemistry A, 2022

2- Correlation of interfacial dilational rheology and processing of 2D Materials liquid crystals: A case-study of graphene oxide liquid crystal phases, Iranian Journal of Physics Research 20 (3), 515-524, 2020

3- Laser-assisted tunable optical nonlinearity in liquid-phase exfoliated MoS2 dispersion, Applied Physics A 124 (10), 692, 2018

4- Superflexibility of Graphene Oxide, PNAS, 2016, 113 (40), 11088-11093

5- Processable 2D materials beyond graphene: MoS2 liquid crystals and fibers, Nanoscale 2016, 8 (38), 16862-16867

6- Liquid crystal mediated self-assembly of porous α-Fe2O3 nanorods on PEDOT:PSS functionalized graphene as a flexible ternary architecture for capacitive energy storage, Particle and Particle Systems Characterization, 2016. 33 (1) : p.27-37

7- Self-assembled multifunctional hybrids: Towards architecting high-performance graphene-based energy storage devices, ACS Central Science, 2015. 1(4): p.206-216

8- Graphene oxide dispersions: tuning rheology to enable fabrication, Materials Horizons, 2014. 1 (3): p.326-331

9- Formation and processability of liquid crystalline dispersions of graphene oxide. Materials Horizons, 2014. 1(1): p. 87-91

10- Spray Pyrolysis of liquid crystalline dispersions of graphene oxide based hybrids: a practical approach towards next generation of 3D isotropic architectures for energy storage applications, Particle and Particle Systems Characterization, 2014

11- Scalable One‐Step Wet‐Spinning of Graphene Fibers and Yarns from Liquid Crystalline Dispersions of Graphene Oxide: Towards Multifunctional Textiles. Advanced Functional Materials, 2013. 23(43): p. 5345-5354

12- Organic Solvent-Based Graphene Oxide Liquid Crystals: A Facile Route toward the Next Generation of Self-Assembled Layer-by-Layer Multifunctional 3D Architectures. ACS nano, 2013. 7(5): p. 3981-3990

13- Self-alignment and high electrical conductivity of ultralarge graphene oxide–polyurethane nanocomposites. Journal of Materials Chemistry, 2012. 22(25): p. 12709-12717

14- Spontaneous formation of liquid crystals in ultralarge graphene oxide dispersions. Advanced Functional Materials, 2011. 21(15): p. 2978-2988

Summary in English and Photo

The successful commercialization of 2D materials requires the integration of these fascinating materials into real-world applications and devices. Since 2D materials are the active components that determine the performance of these systems, it is important to rationally design, engineer and manufacture hierarchical hybrid architectures at both nano- and macroscale that can enjoy all of the necessary requirements for given applications. However, conventional micro-fabrication techniques have proven to be inconvenient in the construction of cost-effective micro-devices, thus limiting their widespread use. To address this challenge, inspired by nature, we proposed that through a simple, yet novel solvophobic self-assembly processing approach based on 2D materials liquid crystals, nacre-mimicking, hybrid composite materials (consisting of 2D and 1D materials) can be made incorporating many of the exciting attributes of graphene and other 2D materials into practical real-world devices with emphasis on energy storage devices and thermoelectric materials. To date, I have designed and fabricated many different architectures combining LC GO as a template to self-assemble and engineer hybrid materials spanning a long list of polymers and metal oxides for different applications using a number of state-of-the-art technologies including 3D printing, fiber spinning, spray pyrolysis, etc. However, this method still has shortcomings in which it fails to frame a clear picture on how we can regulate the self-assembly processes required for the fabrication of intrinsically complex vdW heterostructures using simple solvent-based methods. Addressing this challenge and understanding what forces are the governing factors behind such self-assembly processes is the next logical step that should be taken to describe the dynamics of these forces and exploit them to fabricate state-of-the-art multifunctional devices.

The successful commercialization of 2D materials requires the integration of these fascinating materials into real-world applications and devices. Since 2D materials are the active components that determine the performance of these systems, it is important to rationally design, engineer and manufacture hierarchical hybrid architectures at both nano- and macroscale that can enjoy all of the necessary requirements for given applications. However, conventional micro-fabrication techniques have proven to be inconvenient in the construction of cost-effective micro-devices, thus limiting their widespread use. To address this challenge, inspired by nature, we proposed that through a simple, yet novel solvophobic self-assembly processing approach based on 2D materials liquid crystals, nacre-mimicking, hybrid composite materials (consisting of 2D and 1D materials) can be made incorporating many of the exciting attributes of graphene and other 2D materials into practical real-world devices with emphasis on energy storage devices and thermoelectric materials. To date, I have designed and fabricated many different architectures combining LC GO as a template to self-assemble and engineer hybrid materials spanning a long list of polymers and metal oxides for different applications using a number of state-of-the-art technologies including 3D printing, fiber spinning, spray pyrolysis, etc. However, this method still has shortcomings in which it fails to frame a clear picture on how we can regulate the self-assembly processes required for the fabrication of intrinsically complex vdW heterostructures using simple solvent-based methods. Addressing this challenge and understanding what forces are the governing factors behind such self-assembly processes is the next logical step that should be taken to describe the dynamics of these forces and exploit them to fabricate state-of-the-art multifunctional devices.

|

|